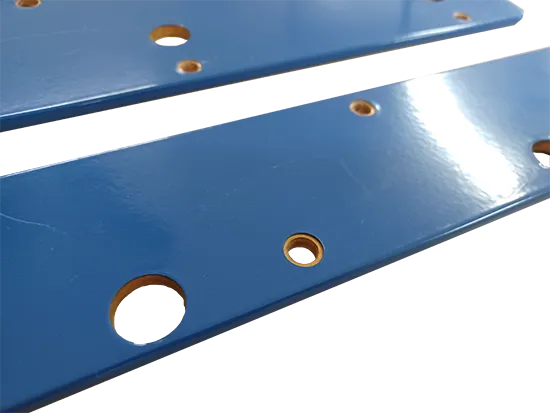

- Resicoat epoxy powder is an excellent electrical insulator with good resistance against chemicals, heat & moisture.

- It has got good strength and adhesion to conductors like copper and aluminium.

- Product after powder coating could bear a service temperature of upto 130 deg.

-

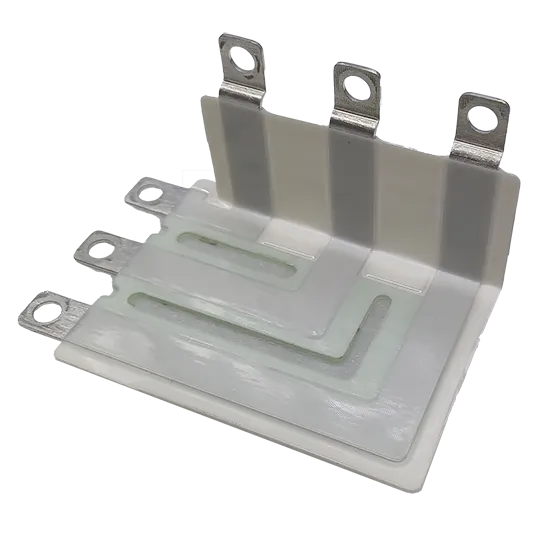

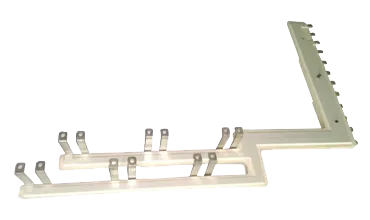

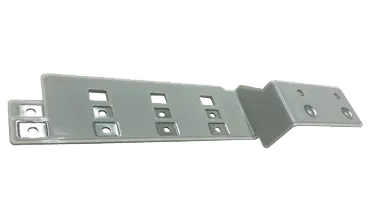

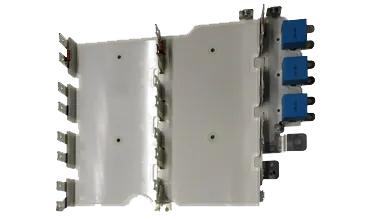

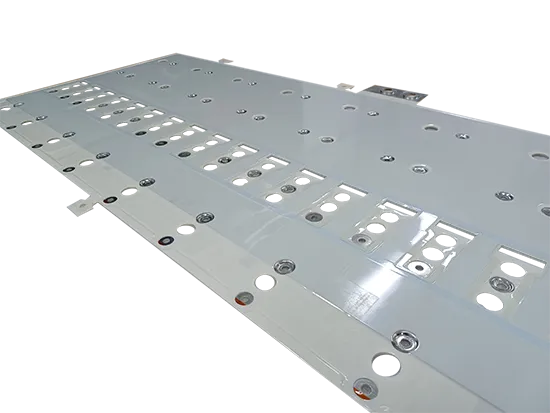

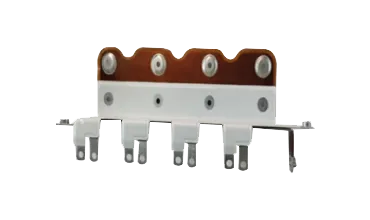

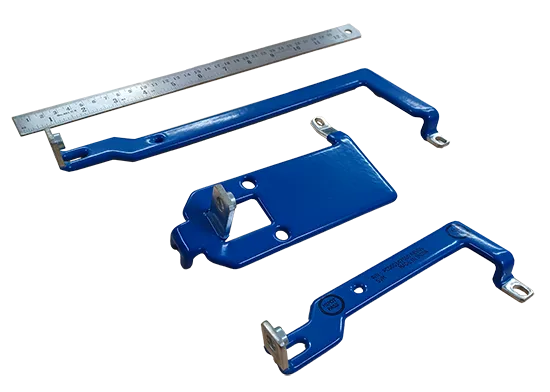

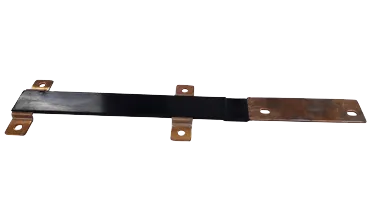

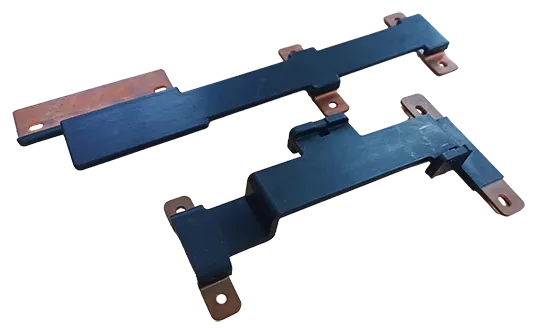

Bus bar type

Epoxy powder coated

-

Length

350mm

-

Width

390mm

-

Height

65mm

-

Conductor

Copper

-

Conductor thickness

3mm

-

Plating

Tin, Gold

-

Operating Temp

130°C

Typical applications :

- Interconnection of Capacitor Links, DC Link, IGBT Power Module, Power and Measuring Components, High Current Inductors etc for various markets like Power Electronics, Wind Energy, Solar Energy, Aerospace Application, Military Application, and Transportation.

Compliance and certifications

UL 94V0

RoHS

Would you like to ajust a little something?

Customize it

1document

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service.

Contact