Integrated Solutions

|

Name

|

Download

|

Diameter (Outside Diameter)

|

Description

|

Type of signals

|

|---|---|---|---|---|

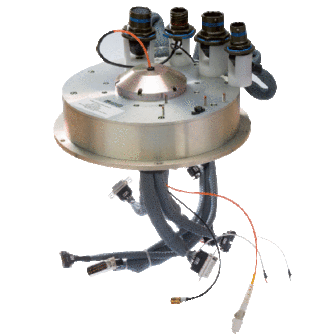

| Slip Ring + encoder + FORJ + RF-RJ | - | Not available | Not available | |

| L-Band Rotary Joints | - | Bandwith 1GHz | Data | |

| Slip Ring + FORJ | - | Fiber Optic | Data | |

| Encoder + FORJ | - | Fiber Optic | Data | |

| Slip Ring + Hydraulic | - | Hydraulic or pneumatic | On request | |

| Slip Ring + Encoder + FORJ | - | Not available | Not available |

Integrated Solutions

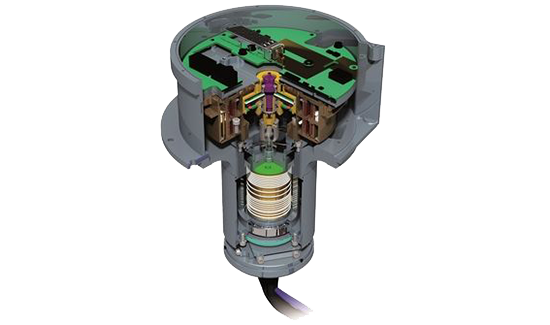

Slip rings transmit information via electric contacts (brushes rubbing against tracks).

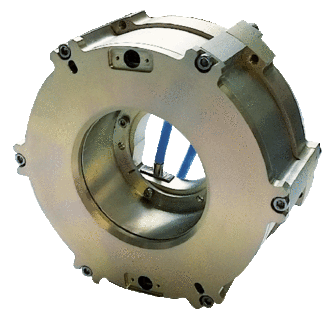

Exxelia has been developing slip rings for over 50 years and our knowhow enables us to integrate different levels of technology in our Rotary Joint Assemblies (RJA) such as: Fiber Optic Rotary Joints (FORJ), Radio Frequency Rotary Joints (RFRJ), Encoders and more, giving our clients products they can rely on for smooth transmission of high power levels, HD-SDI signals, high speed Ethernet and more even in challenging environments. This is why our slip rings are typically found in demanding and sophisticated rotating machinery and equipment, such as radars, industrial robots, drilling tools, embarked optronics, surveillance systems and rotating sensors.

Our slip rings mechanical interfaces can be engineered to suit your needs and optimized to reduce your system’s cluttering. In applications where space or size constraints are a consideration, Exxelia’s designs are giving the option to consider hollow shaft, pancake designs and other tailor made structures to integrate seamlessly in your system.