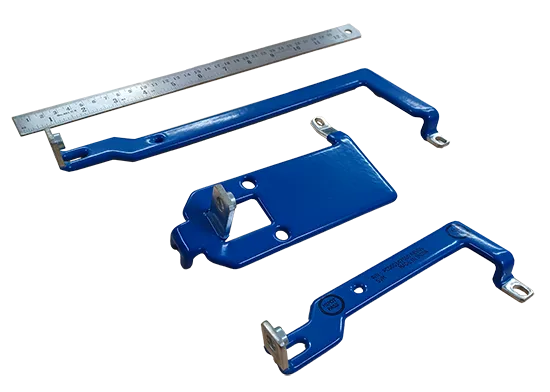

Powder coated bus bars

|

Name

|

Download

|

Bus bar type

|

Length

|

Width

|

Height

|

Conductor

|

Conductor thickness

|

Plating

|

Operating Temp

|

|---|---|---|---|---|---|---|---|---|---|

| Powder Coated bus bar copper | Epoxy powder coated | 350mm | 390mm | 65mm | Copper | 3mm | Tin, Gold | 130°C | |

| Powder Coated bus bar Aluminium | Epoxy powder coated | 290mm | 90mm | 25mm | Aluminum | 1mm | Tin, Gold | 130°C | |

| Powder Coated bus bar Aluminium 2 | Epoxy powder coated | 510mm | 110mm | 50mm | Aluminum | 6mm | - | 130°C | |

| Sub-assembly bus bar | Epoxy powder coated | 500mm | 320mm | 105mm | Copper | 2mm ~ 3mm | Tin | 130°C |

Powder coated bus bars

Powder Coated Busbars are an engineered solution for electrical insulation using advanced powder coating technology on electrical conductors. This solution is optimized for applications requiring reliable electrical insulation in demanding environmental conditions.

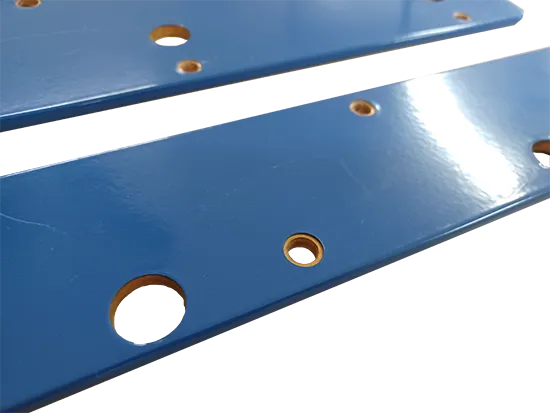

Technical Specifications :

The powder coating process utilizes premium-grade materials including AKZONOBEL HJD22QF ECA 1283, Interpon 100 AN137QF, Resicoat HGC20R, and Resicoat HLF 59R EL.

Performance Characteristics :

The Resicoat epoxy powder coating delivers superior electrical insulation properties while maintaining excellent chemical, thermal, and moisture resistance. The coating demonstrates strong adhesion characteristics to copper and aluminum conductors.

Operational parameters:

- Service temperature rating: Up to 130°C

- Coating thickness range: 0.3mm - 0.6mm

- Dielectric strength: 40-45 kV/mm

- Mechanical stability: Enhanced resistance to vibration and shock loads

Meets industry standards:

- UL-94 V-0 flame classification

- RoHS environmental compliance