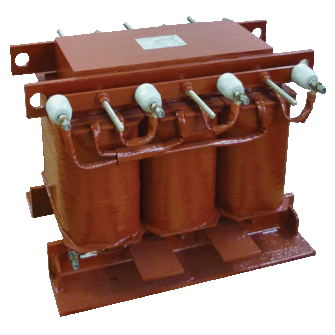

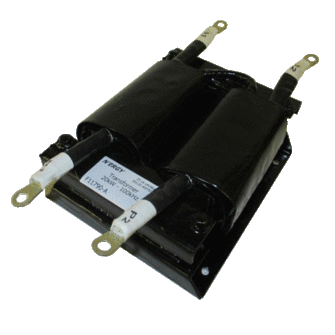

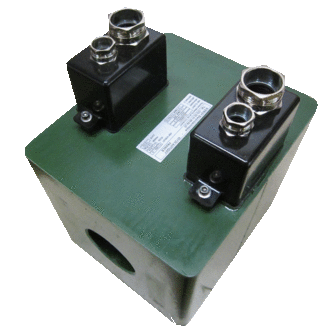

- 3-phase embedded transformer

- Leakage inductance 560 uH

- Pulsed air flow 300l/s

- Weight 520kg

- Part of the switching power supply to provide 400V (3-phase)

-

Mounting

Free (In-Line)

-

Frequency

50Hz

-

Power

150kW

Compliance and certifications

IEC

Would you like to ajust a little something?

Customize it

1document

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service.

Contact