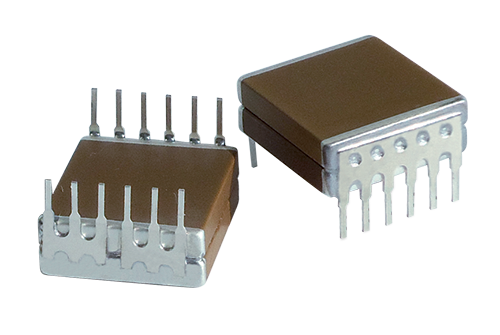

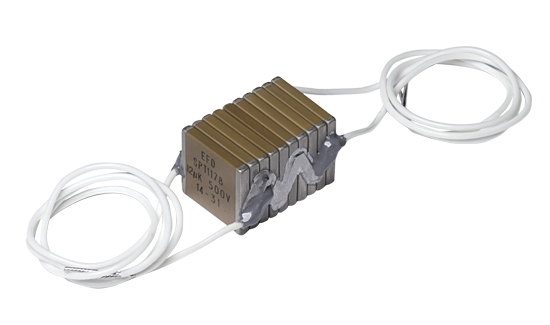

High Temperature stack

High temperature

Custom example

- 10 capacitors 12µF 500V

- Tolerance +/-10%

- Dielectric X7R

- Up to 175°C

-

Capacitance

12µF

-

Tolerance

±10%

-

Operating Temp

-55°C ~ 175°C

-

RoHS

ROHS

-

Voltage Rated DC

500V

Typical applications :

- Fossil fuels

- Perfect for downhole tools

Compliance and certifications

Custom Qualification Plan

Would you like to ajust a little something?

Customize it

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service.

Contact