Exxelia à Space Tech Expo

Exxelia exposera du 22 au 24 mai sur le salon Space Tech Expo USA.

ESA QPL Film Capacitors

PM907S and PM948S are full series of Polyester Film Capacitors. PM907S products are suitable for voltages from 50V up to 1250V and offer capacitance values from 82nF up to 180μF. PM948S can be used from 50V up to 630V with capacitance values from 22nF up to 47μF. Both series can support extreme conditions with temperatures from -55°C to +125°C, and offer high energy density, low ESR & ESL and high RMS current.

PM907S and PM948S are full series of Polyester Film Capacitors. PM907S products are suitable for voltages from 50V up to 1250V and offer capacitance values from 82nF up to 180μF. PM948S can be used from 50V up to 630V with capacitance values from 22nF up to 47μF. Both series can support extreme conditions with temperatures from -55°C to +125°C, and offer high energy density, low ESR & ESL and high RMS current.

Film capacitor Series PM907S and PM948S are ESA QPL certified according to the ESCC Detail Specification No. 3006/025 and 3006/026

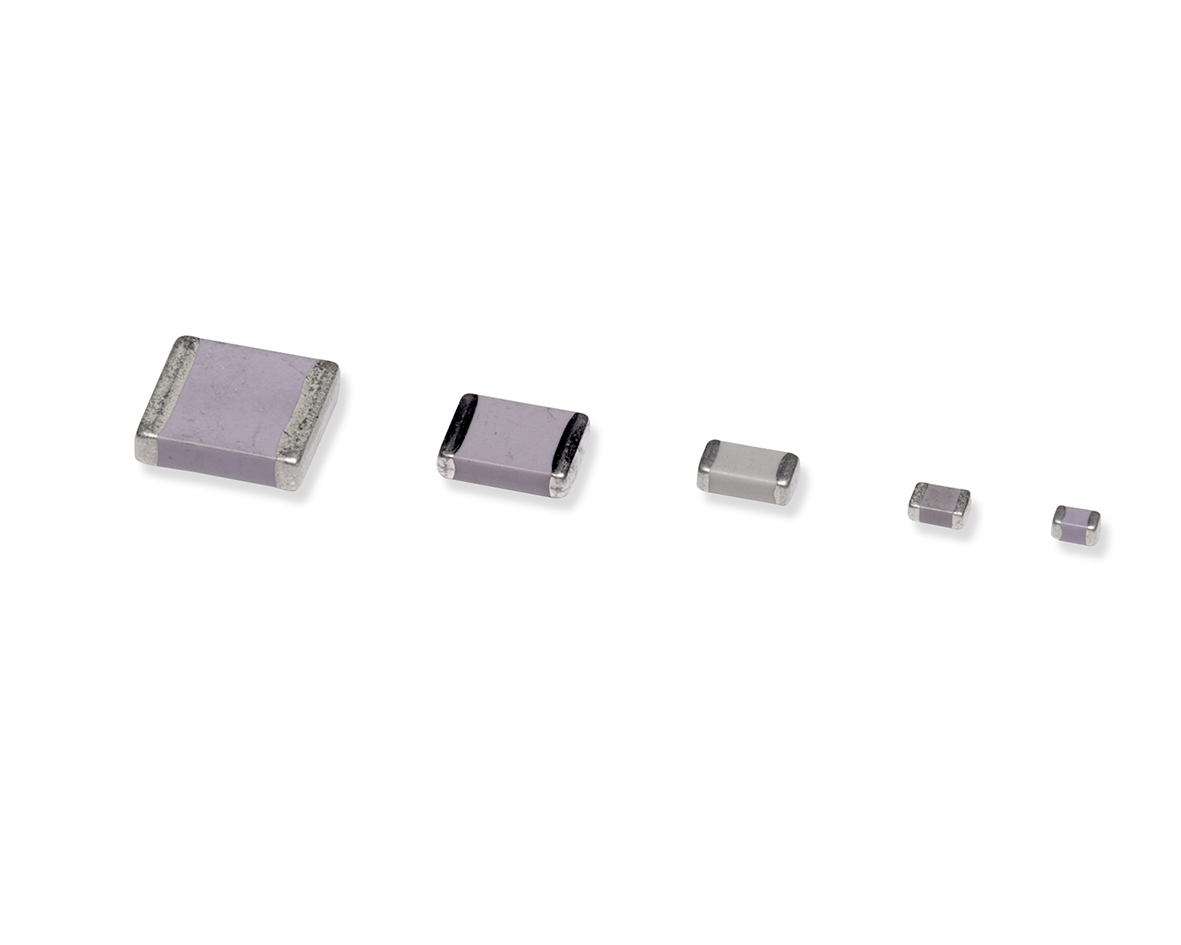

Smallest ESA QPL Ceramic Capacitor of the Market

Exxelia ranges of low voltage MLCC for surface mounting, CEC19 and CNC19, have achieved the ESA Qualified Part List status under the criteria of the European Space Component Coordination’s (ESCC) 3009/042 and 3009/043 respectively. The 0402 size QPL-qualified parts are available from 10V to 25V, enabling substantial miniaturization and cost-saving. They are available either in the very stable NPO dielectric (type 1) or the high capacitance X7R (type 2). CEC and CNC series combine high capacitance values with high thermal and voltage stability. Versions with polymer terminations are also QPL-certified.

Exxelia ranges of low voltage MLCC for surface mounting, CEC19 and CNC19, have achieved the ESA Qualified Part List status under the criteria of the European Space Component Coordination’s (ESCC) 3009/042 and 3009/043 respectively. The 0402 size QPL-qualified parts are available from 10V to 25V, enabling substantial miniaturization and cost-saving. They are available either in the very stable NPO dielectric (type 1) or the high capacitance X7R (type 2). CEC and CNC series combine high capacitance values with high thermal and voltage stability. Versions with polymer terminations are also QPL-certified.

Miniature EMI filters for space application

Exxelia’s gold-plated glass-sealed EMI filters SFC030 is the solution of choice to protect several embedded power supplies and data lines. These small and reliable filters are available up to 5A @ 200V and 22nF. Available in a Kovar package, the better alternative to steel for enhanced temperature cycling resistance, all Exxelia’s EMI filters for space are ESA qualified according to ESCC 3008. Thanks to this extensive experience in stringent ESA testing, Exxelia is able to adapt the tests of any filter according to any need (example: SMD 20A chip, 0pF capacitor value for an arrays of filters).

Exxelia’s gold-plated glass-sealed EMI filters SFC030 is the solution of choice to protect several embedded power supplies and data lines. These small and reliable filters are available up to 5A @ 200V and 22nF. Available in a Kovar package, the better alternative to steel for enhanced temperature cycling resistance, all Exxelia’s EMI filters for space are ESA qualified according to ESCC 3008. Thanks to this extensive experience in stringent ESA testing, Exxelia is able to adapt the tests of any filter according to any need (example: SMD 20A chip, 0pF capacitor value for an arrays of filters).