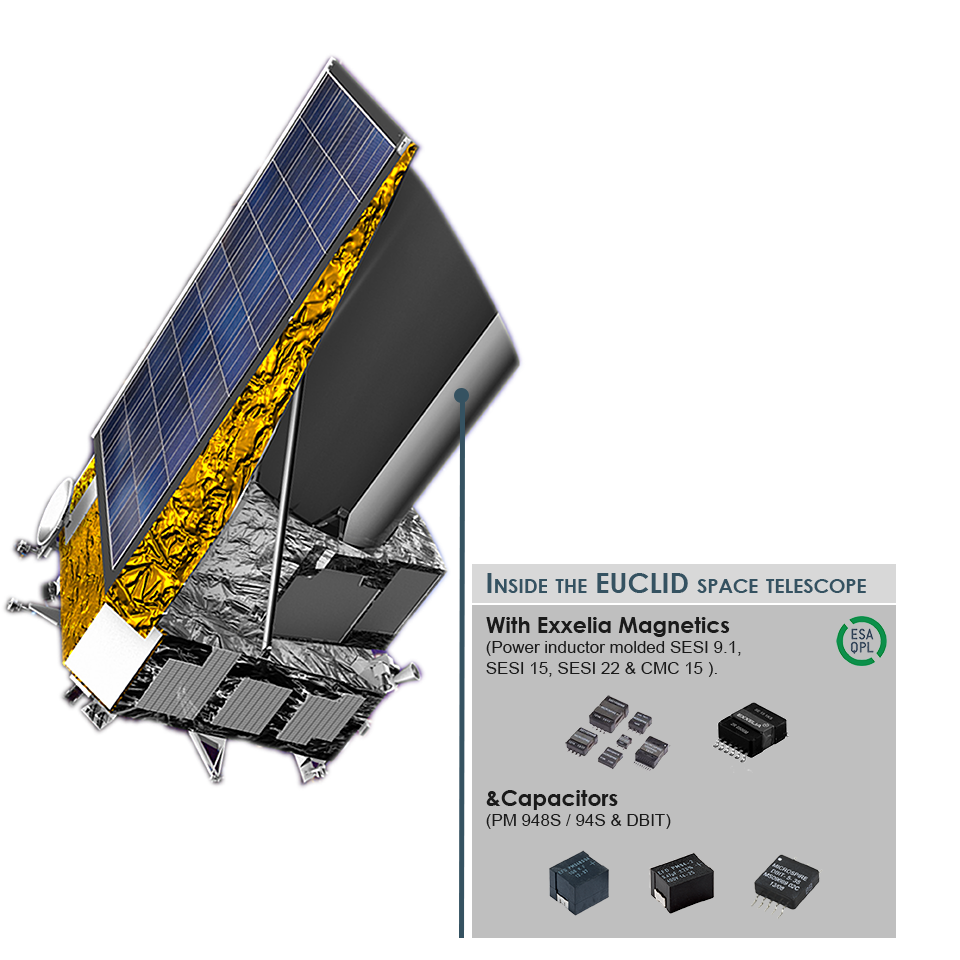

Euclid: The ESA mission embeds our magnetic components and capacitors

Our magnetic components and capacitors are on board ESA's latest mission: Euclid.

This remarkable achievement comes on top of our successful participation in ESA's JUICE mission and the presence of our components on board NASA's Perseverance rover.

Euclid is an ambitious space mission of the European Space Agency (ESA) which aims to map the observable Universe and investigate mysterious dark energy and dark matter. The satellite will study galaxies that are at different distances from Earth using a 1.2m diameter telescope that carries two instruments: the Visible Light Observing Imager (VIS) and the Near Infrared Spectro-Imager (NISP).

We are proud to have been selected as the supplier of high reliability passive components for this crucial mission. Our magnetic components (CMC 15, SESI inductor 9.1, 15 & 22) and capacitors have (PM 948S, PM 94S, DBIT X3S) been carefully designed and manufactured to meet the extreme requirements of space (ESA QPL) and play a key role in the success of the Euclid mission (we are inside PCDU = Power conditioning distribution unit).

Our expertise and our experience in the design and manufacture of custom-made passive electronic components for the space sector, allow us to meet the most stringent requirements of the aerospace industry. We are determined to maintain our position as a trusted supplier for renowned space missions.

Our expertise and our experience in the design and manufacture of custom-made passive electronic components for the space sector, allow us to meet the most stringent requirements of the aerospace industry. We are determined to maintain our position as a trusted supplier for renowned space missions.

Image crédit : ESA/C. Carreau,CC BY-SA 3.0 IGO